BMA Belting’s range of neoprene rubber timing belts surpasses all expectations of a high quality product.

Advantages include:

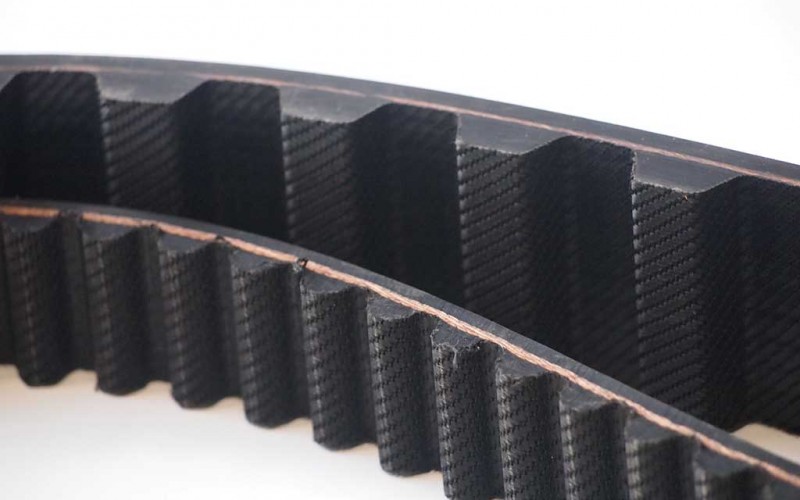

- The extra durable, highly flexible neoprene backing provides excellent abrasion and wear resistance – especially important if power is transmitted from the back of the belt. Backing also guards the tensile cords against oil, grease, dirt and moisture

- Continuous, helically-wound high strength fiberglass tensile cords guarantee dimensional stability to eliminate take up adjustments.

- Heavy torque loads won’t fatigue this super strong cord. S and Z orientation of the cords aid in minimizing belt tracking problems

- Precision formed, oil and heat resistant neoprene teeth have a shear resistance equal to the tensile strength of the belt (under standard ‘6 teeth in mesh’ tests).

- Tooth design and tight manufacturing tolerances provide full surface contact between belt and pulley for smooth running characteristics.

- The tooth surface is protected by a low friction, clean running, wear resistant woven nylon facing.

- Seamless construction eliminates vibration