BMA Belting roller lagging is a service offered to clients who experience issues of conveyor belt slippage on drive and idler rollers. Using BMA Belting roller lagging helps increases the friction value between drive roller and belt, and is effective to use on conveyors which are affected by water, ice, oils or sludge. Not only does it help prevent belt slippage, but roller lagging can also assist in protecting the pulleys from damage as well as allowing for lower belt tensioning and greater driving power, thus increasing belt life span expectancy.

BMA Belting are able to lag most size rollers both in-house or onsite. Alternatively, materials and adhesives can be sold as a kit so customers can lag their own rollers, with our helpful technical staff available to offer training and assistance if required.

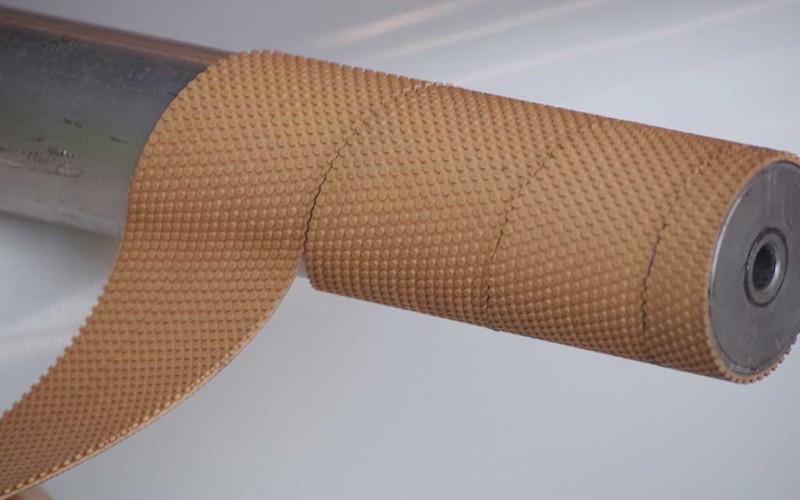

BMA Belting’s roller lagging product range includes:

- High quality friction tape with cotton backing

- Self-adhesive lagging tape for quick fix situations

- 10mm-12mm diamond lagging in natural and FRAS rubber

- Polyurethane moulded lagging

- Food grade material